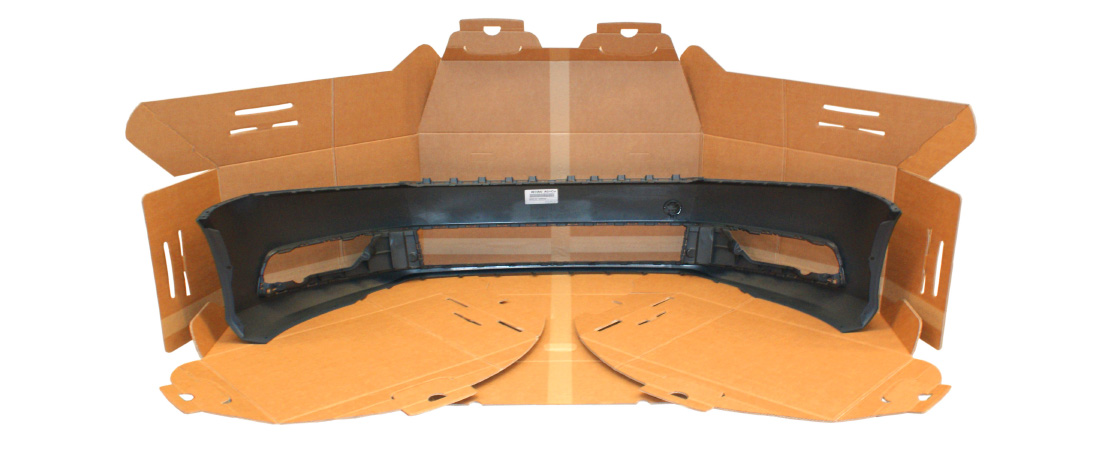

Packaging development for manufacturers

It can be useful in many cases to incorporate packaging when developing new products. This ensures that right from the product launch, the costs arising from goods and transport packaging are kept as low as possible.

Considerations such as single-material packaging made from renewable resources or the development of particularly safety-critical components can be part of the development process, taking into account environmental options just as much as a CO²-optimized delivery structure.

It could also be about a safe consolidated shipment of production parts for processing, about long-term protective storage packaging or about outer packaging suitable for export.

Explosive goods safely packed

Custom requirements need custom solutions. Frequently, highly sensitive or hazardous goods have to be packed and shipped.

Nordpack also develops solutions meeting the highest safety requirements with appropriate certification in this sector. For maximum but still cost-efficient protection of e.g. airbags, we thus offer the MULTi-Cargo FiREbox.

This packaging reliably passes UN test 6c (bonfire) for class 9 and thus fulfils the highest requirements for hazardous goods packaging.

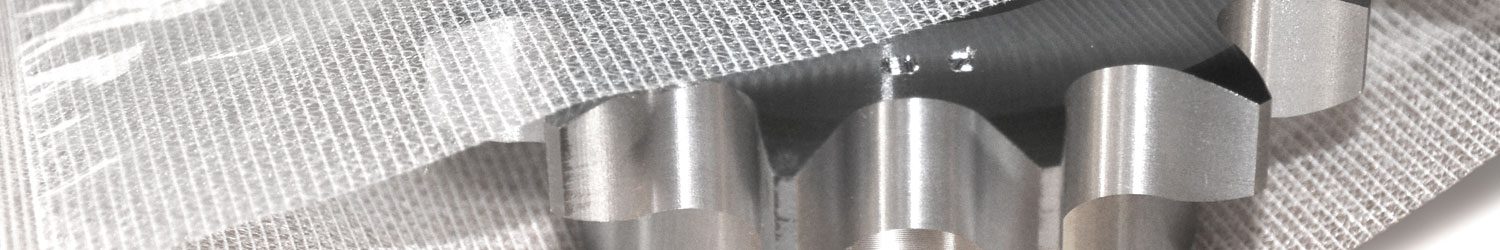

Corrosion prevention with VCI materials

Transport packaging has to meet the highest standards so you can deliver corrosion-free, dry, clean and ready-to-use parts to your customers anywhere in the world.

Using VCI protection contributes to meeting these standards. Nordpack offers a variety of VCI carrier materials for this. In our production facility, we can process VCI-treated corrugated board, creating box dividers and intermediate layers.

All common films and papers are available so you can choose the ideal VCI carrier material for your specific requirements. These can be deliverd as custom-sized materials or on rolls. Thus, a tailor-made product grows with your requirements.