Modular systems for industry, trade and logistics

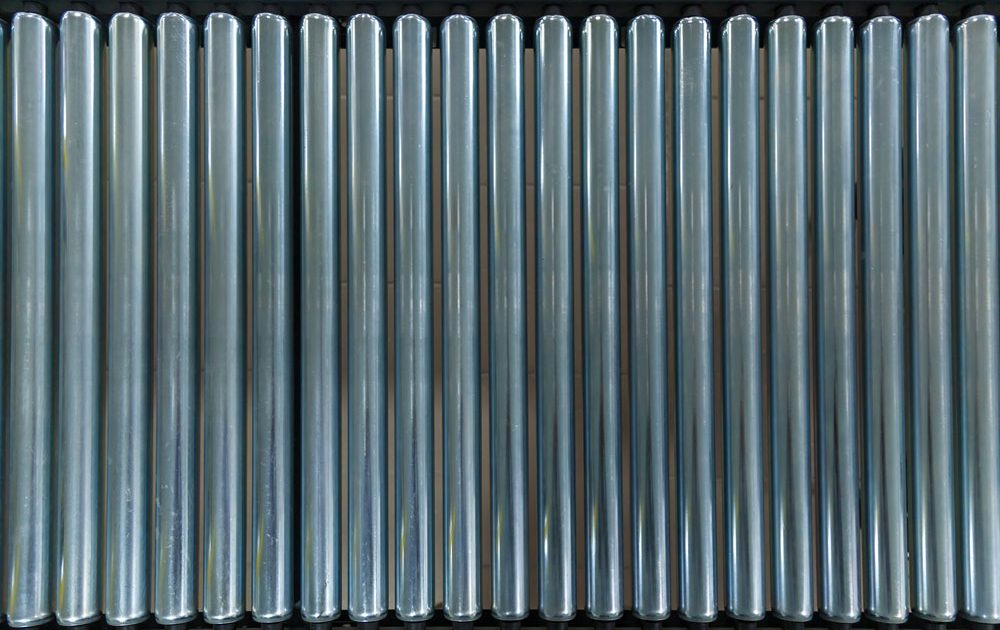

Roller conveyors, also called conveying systems, are modular components transporting items such as boxes, cartons or crates over short or long distances to their destination.

The different components (straight, curved or merges) can be combined as needed and adjusted to the work environment.

Application/uses

More and more companies rely on conveyor belt technology in order to streamline production processes. The systems are quick to set up and ensure smooth operation of in-plant goods traffic. They can be combined with workstation systems.

The small roller conveyors or conveyor belts are integrated into packaging lines and transport workpieces, boxes, crates and much more automatically from one place to another. These systems shorten production worker’s routes and save on production and personnel cost.

The conveyors are frequently used in dispatch, in warehouse logistics and in production.

Composition

The conveyor systems consist of many different, separate modules that can be combined as needed.

- Straights

The straight conveyor modules take care of smooth transport of goods over short or long distances. The individual rollers can be powered electronically or move automatically (with a continuous slope to the roller structure). The continuous side or frame pieces stop the goods from falling off. - Curves

The curved sections of roller conveyors allow for changes of direction. The conical alignment of the rollers ensures that the goods remain between the side walls. - Merge modules

Merges feed two conveyors together, guiding conveying systems from different production locations to one joint end point (such as a loading bay). The merge joins two roller conveyors by using gaps in the material flow – avoiding collisions and damage. - Diverter modules

The diverter uses swivelling rollers to channel materials out and guide them onto another conveying system without disturbing or interrupting the transport flow of the main conveying system. - Transfer modules

The transfer module can sort goods from the conveying system. These modules are often used with sensors that identify faulty or damaged goods and transmit the sort command to the transfer module.

Roller conveyor designs

Conveyor belts and roller conveyors are used for light, medium and heavy goods and can be automated or non-automated.

The non-automated systems feature a constant slope, using gravity to transport the goods. In addition, the roller conveyors can be equipped with sensors, motors and a variety of other control elements.

Downloads

Nordpack FSC certificate (PDF, 852KB)

Nordpack DIN EN ISO certificate (PDF, 272KB)

CONTACT

Sales Team Protect, Fill & Secure

Phone: +49 5136 8004-129

Fax: +49 5136 8004-130