Don’t let your cargo slip

Friction is why we are able to move without constantly slipping. Without friction, we would always be walking on ice. Friction is our slip inhibitor. Lack of friction can be highly dangerous when transporting cargo. Unsecured cargo can quickly slip when braking.

To stop accidents like this happening, slip-inhibiting materials are used for load securing. There are many different kinds of slip-inhibiting materials. Every slip-inhibiting material can influence friction differently, depending on use. This is why it is mandatory to establish the respective coefficient of sliding friction! Independent testing institutes such as DEKRA or the Fraunhofer Institute issue test certificates for sliding friction.

The coefficient of sliding friction for anti-slip mats must not be lower than µ 0.4 according to VDI standard 2700 Part 15. The higher the factor, the higher the friction. Safety Grip is a latex-coated solid cardboard anti-slip mat for use in pallet securing and load securing in the transport sector. Safety Grip is part of Nordpack GmbH’s in-house brand Multi Cargo.

Application

Load safety is of great importance nowadays and thus Nordpack has made it its goal to manufacture a slip-inhibiting mat that can be disposed of as waste paper after use, in contrast to conventional anti-slip mats made from rubber granules.

They are used for load securing, ensuring the cargo does not slip during transport. It is important to make sure the contact areas are swept clean and free from oil, grease or ice, as otherwise we cannot guarantee reliable protection from slippage. Safety Grip is easy to use either as an anti-slip mat under the pallet, i.e. between lorry bed and pallet, flat on the pallet or as intermediate layer between cargo units such as cardboard packaging.

Safety Grip is normally applied for single use only as with possible soiling, the coefficient of sliding friction can no longer be guaranteed when used repeatedly.

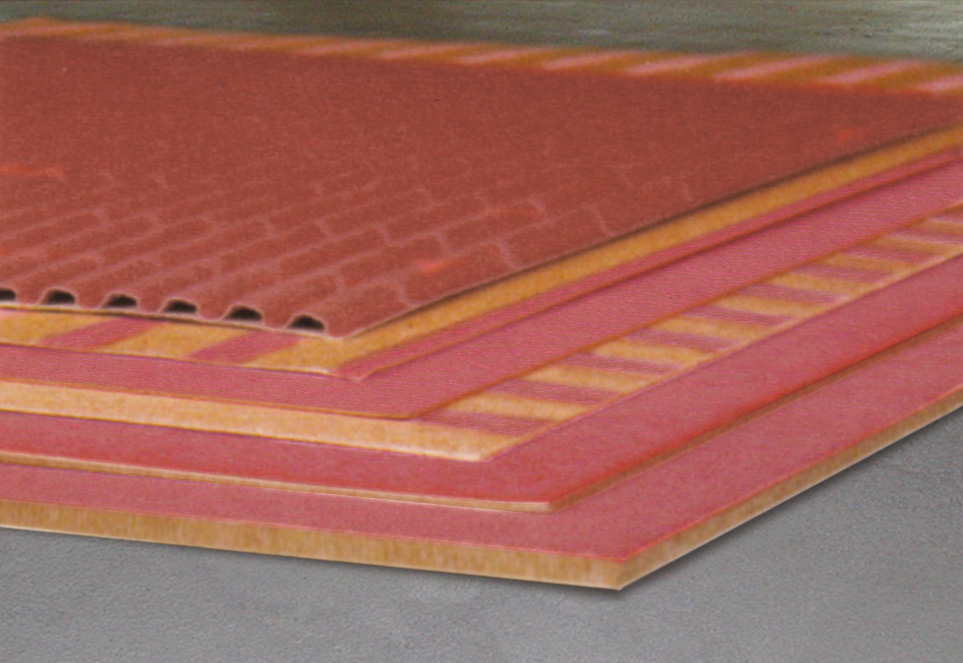

Composition

Safety Grip is a paper-based anti-slip mat. The solid cardboard is coated on both sides, the rubberized latex coating on the outer sides is what results in the slip-inhibiting properties.

The mats are 0.4 mm to 4.5 mm thick depending on finish. Safety Grip is food safe.

Designs

Naturally, the product is available in a number of finishes:

- Safety Grip board (thickness 0.4 mm & 0.8 mm )

- Safety Grip soft ( 2.2 mm & 4.5 mm )

- Safety Grip wave ( 5.0 mm; suitable for drums)

All products available in different dimensions. Safety Grip board products also available as Safety Grip board stripe.

Product video

By loading the video, you agree to YouTube's privacy policy.

Learn more

Numbers and Data

| Design | Size (mm) |

THICKNESS (mm) |

ITEMS (PALLET) |

|---|---|---|---|

| SAFETYgrip paper stripe | 740 x 1140 | 0,20 | 2000 |

| SAFETYgrip paper stripe | 940 x 1140 | 0,20 | 2000 |

| SAFETYgrip paper stripe | 1140 x 1140 | 0,20 | 2000 |

| Special dimensions on request from at least 18000 m2 up to a max. of 1140 mm wide and 1140 mm long! | |||

| SAFETYgrip board stripe | 800 x 1200 | 0,40 | 1000 |

| SAFETYgrip board stripe | 1000 x 1200 | 0,40 | 1000 |

| SAFETYgrip board stripe | 800 x 1200 | 0,40 | 1000 |

| SAFETYgrip board | 1000 x 1200 | 0,40 | 1000 |

| SAFETYgrip board | 1150 x 1150 | 0,40 | 1000 |

| SAFETYgrip board | 1200 x 1250 | 0,40 | 1000 |

| Custom sizes cut from standard sizes are available from 1 pallet! | |||

| Special dimensions on request from at least 8000 m2 up to a max. of 1200 mm wide and 1250 mm long! | |||

| SAFETYgrip board stripe | 800 x 1200 | 0,80 | 1000 |

| SAFETYgrip board stripe | 1000 x 1200 | 0,80 | 1000 |

| SAFETYgrip board | 800 x 1200 | 0,80 | 1000 |

| SAFETYgrip board | 1000 x 1200 | 0,80 | 1000 |

| Custom sizes cut from standard sizes are available from 1 pallet! | |||

| Special dimensions on request from at least 8000 m2 up to a max. of 1200 mm wide and 1250 mm long! | |||

| SAFETYgrip soft | 200 x 150 | 2,20 | 10000 |

| SAFETYgrip soft | 400 x 150 | 2,20 | 5000 |

| SAFETYgrip soft | 600 x 150 | 2,20 | 5000 |

| SAFETYgrip soft | 800 x 150 | 2,20 | 2500 |

| SAFETYgrip soft | 1000 x 150 | 2,20 | 2500 |

| SAFETYgrip soft | 1200 x 150 | 2,20 | 2500 |

Friction

Friction is due to the characteristics of the contact areas of two bodies. In a microscopic sense, two bodies “interlock” or “exert a hold on each other.” With rough surfaces, great forces are needed to move the bodies relative to one another.

With smooth surfaces, little force is needed. A “lubricating film” will further reduce the force needed. Once a sliding movement has begun, the surface contact becomes less intense and the necessary sliding force becomes less than at the beginning. This is why a distinction is made between static friction (push start) and sliding friction (pushing on).

A vertical force results in the need for a corresponding horizontal force to pull a block from its position. This retention force is viewed in relation to the weight force. This relation is called “coefficient of friction” (µ).

„µH = 0.2“ would mean for example that a weight force of 1000 N results in a friction force of 200 N. The static friction ensures the block will not move on the substrate unless pulled with a force of more than 200 N. Once the block begins to slide at more than 200 N of pull force, generally less than 200 N are needed to keep the motion going: Sliding friction usually has a lower coefficient than static friction. Now for example, 150 N of pulling force is enough to keep the block in motion: µG = 0.15.

These ratios and coefficients depend on the two friction partners (materials), their surface qualities (especially roughness), temperature, humidity and possible substances between the two bodies (e.g. oil as a lubricant).

CONTACT

Sales Team Specialty Packaging

Phone: +49 5136 8004-129

Fax: +49 5136 8004-130